How a customised, unique solution supports Australia’s Paralympic Medalist as they travel to Paris!

Our organisation recently had a terrific opportunity to work with Australian Paralympic medalist to create some unique, customised equipment for his travels to Paris.

Official team bag wasn't suitable for him

Soon after receiving his official team bags, he realised he was not able to independently carry his luggage. This was where Freedom Solutions Australia’s industrial designer, Mark Matthews-Frederick and the Unique Solutions team came together to create a practical and tailored solution … fast!

The team responded to his urgent request by developing custom handle attachments that were specifically designed for usability and functionality tailored to his abilities, as well as the practicalities of travelling, and stowing bags, checking in on the plane and baggage collection in Paris.

Comfortable and durable solution just under three weeks!

The final design was a unique sleeve assembly, which enables him to transport his bags without needing the help of others and importantly is comfortable, easy to use, durable, and he can reuse it on other bags in the future.

Other important features of the design were to include no damage or modification to the luggage, turning around a solution in just three weeks and the project was fully grant funded.

User-centric process

Our industrial designer, Mark went through the following user-centric process:

1. Assessing the user's requirements

He needed the solution to be secure, comfortable, easy to use and durable. Not to make it a one-time solution, we also looked at how it can be removed and used on other bags in the future.

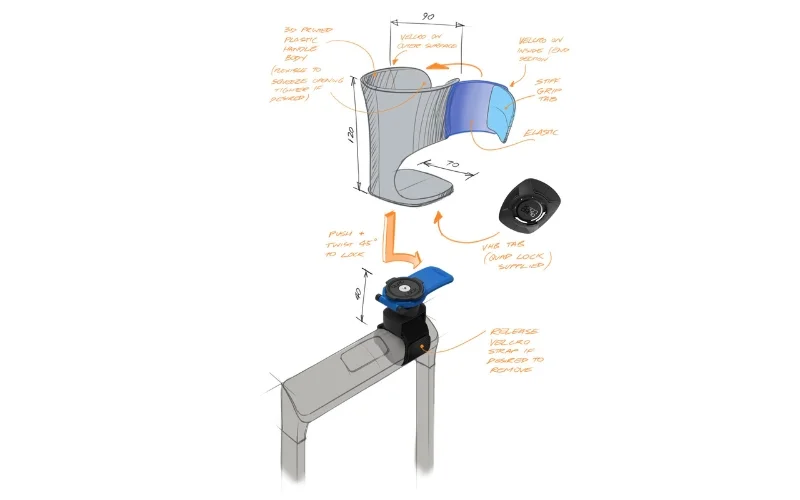

2. Concept design, with resulting explanation and consultation with the user

Using the sketch, Mark throughly explained what the handle sleeve would look like during the consultation.

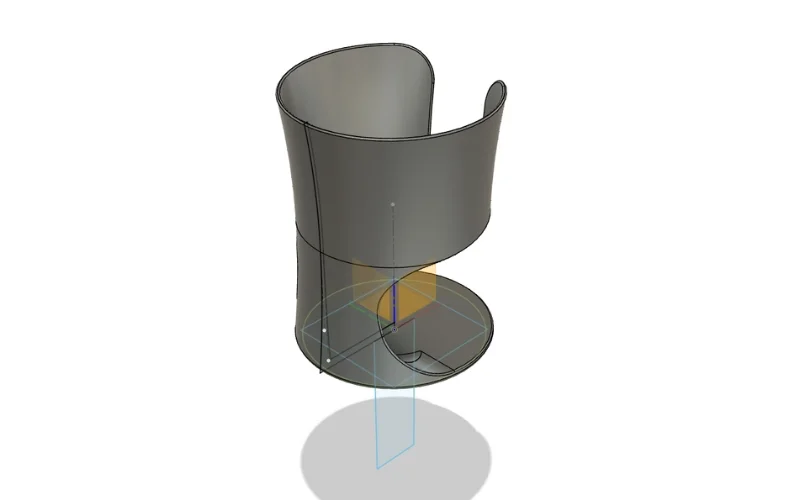

3. 3D CAD

Based on the consultation and the sketch, Mark developed a 3D CAD to be able to create 3D prints.

4. 3D printed prototype

Prototype was printed to trial fitment of the sleeve with him and to test adhering the velcro and strap.

5. Refinement of design

As a result of prototype testing, Mark refined the design and 3D CAD to improve the handle sleeve.

6. 3D print final sleeves

2 versions of the sleeve were printed, for large and small bags. They were assembled with straps and locking mechanism.

7. Handover

At a handover, Mark made sure that the solution met the user’s requirement and it’s comfortable and effective to use.

Do you need a custom-made solution?

Let us know what you need. We’ll create a Unique Solution just for you.